CNC-preshaped SUP/Foil Blank

€0.00*

Available, delivery time: 1-2 weeks

About the product

About the brand

Sustainability

Why is this product a market-leading eco-solution for protecting the environment?

A CNC-preshaped cut is sustainable because it can be processed faster, saves material, is easily reproducible and saves energy. The Agave Blank from Grow Blanks is the first 100% biodegradable, sustainable, and environmentally friendly surf blank available at a large-scale to the surf industry. Crafted from the sisal agave, these blanks use only the waste product of the actual harvest of the farm. Among materials, agave wood is close in weight and density to polyurethane foam, making it the exclusive completely sustainable surf blank for profitable production. Grow Blanks creates jobs for local people, teaches them the trade and creates security for their families.

YouTube

Watch our latest videos for shaping tips and product information. For more videos check out our channel. @ecosurfsupply

Technical details

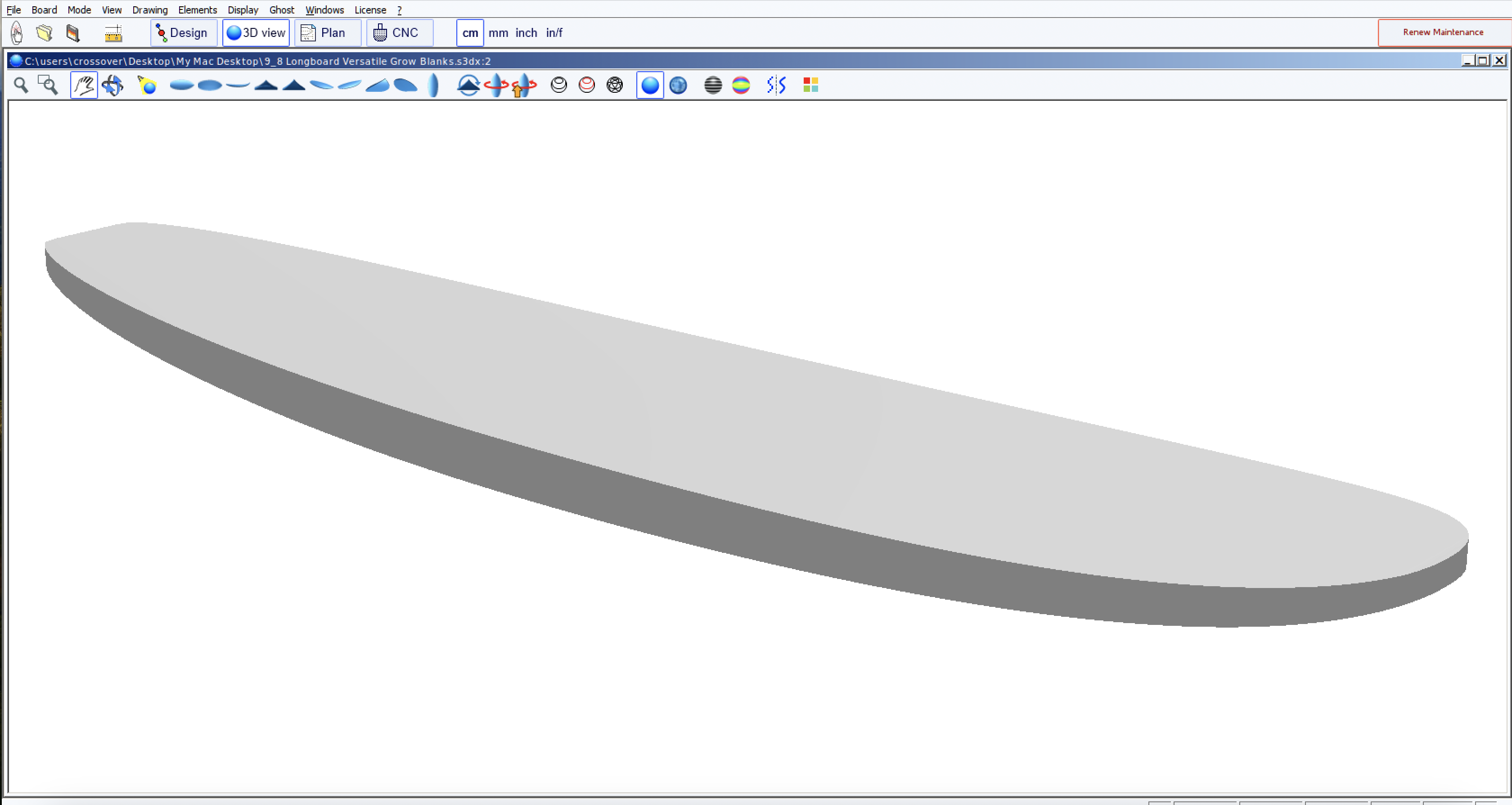

Check if your board outline fits our Blank:

YOU MAY ALSO NEED

Shipping information

PayPal / Klarna / Credit Card

Shipping to all EU countries within 1-2 weeks

Delivery in 3-5 business days to Germany

Customer questions

You can work the agave with the same tools as with conventional foam. We recommend working with the planer as much as possible, as this is originally made for wood and cuts the agave even better than you are used to with foam.

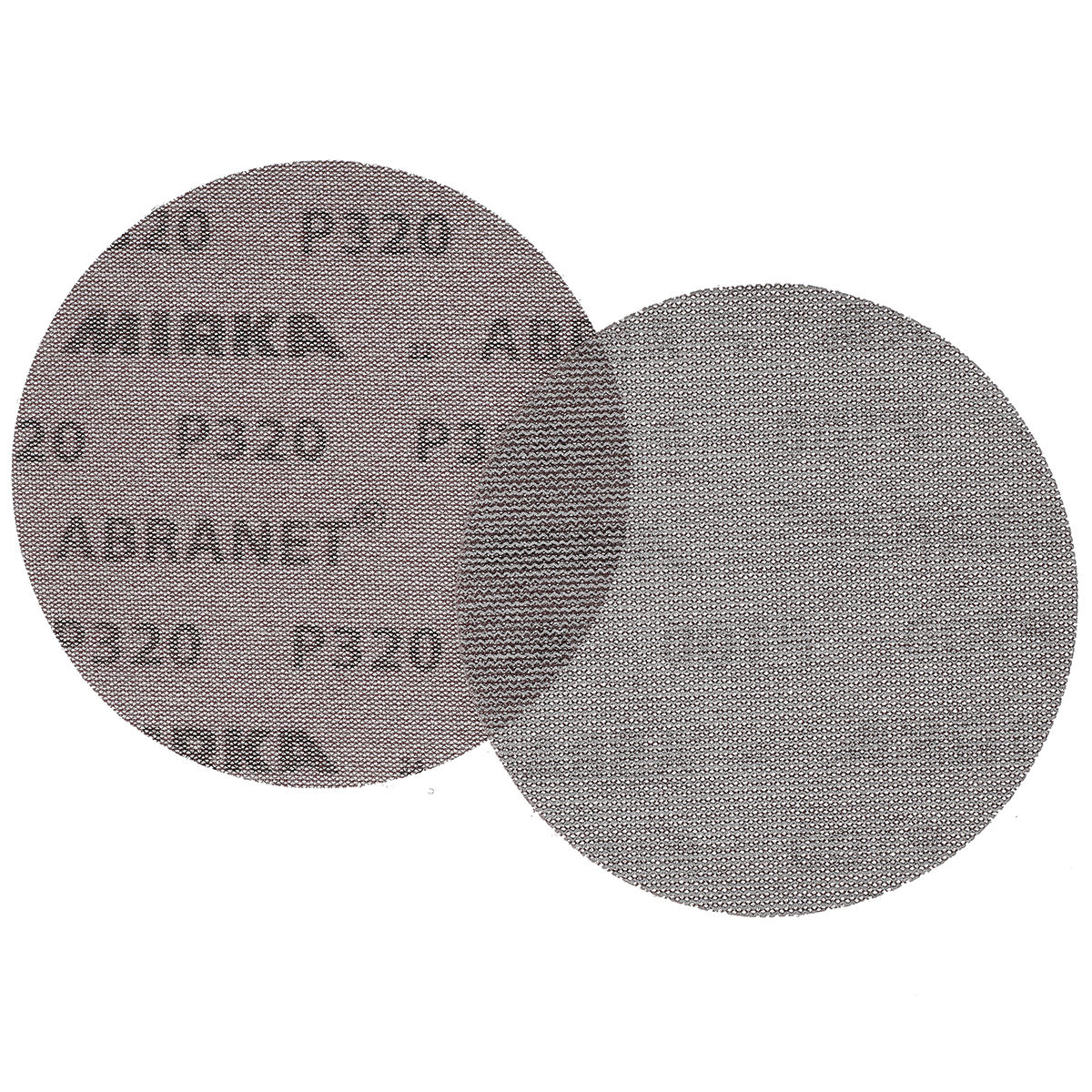

It is good to know that there are 10 to 30 different agave plants in a blank. Growblanks has the ability to offer 3 different densities because of their enormous ranch of plants on the farm which they sort into very light, light and standard poles. When sanding it is important to understand that there are multiple plants in your blank that may have naturally slightly different densities. This can be a little challenge when sanding the nose and tail. Sand with care, watch in between! Learn more about each working step with the agave blank on our tutorial page:

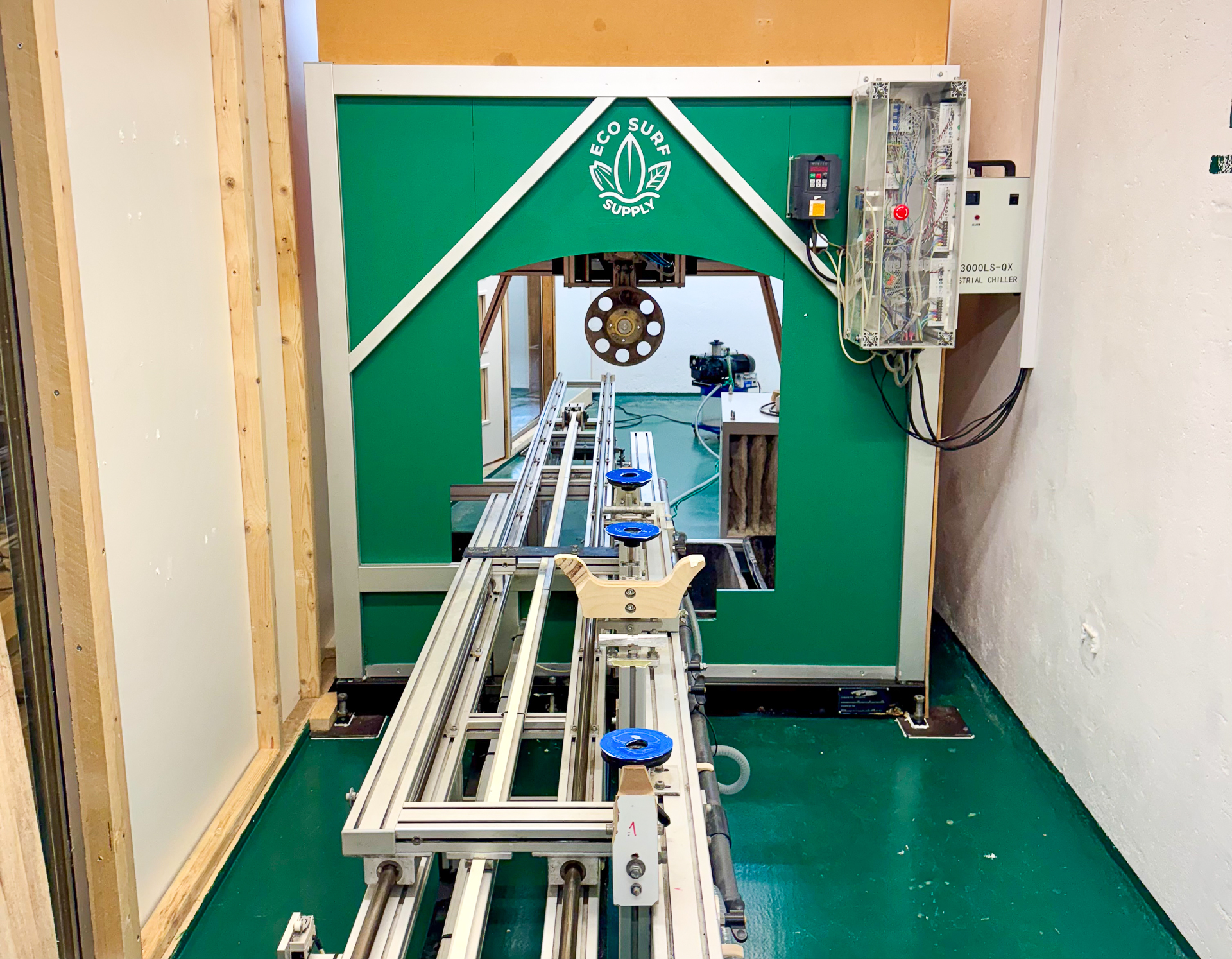

Sure, you can cut an agave blank as regular foam blanks in a CNC Machine. We have successfully tested the Agave blank on all traditionally used CNC machines.

The cleanest cut is produced by the machine with milling blades, which is also used to produce our factory cuts. The following link will take you to our CNC page, where you can find more information about our cutting service. Which machine we use, what kind of cuts we produce, which type of cuts you can order from us and price information.

You can draw your finboxes and cut them as usual. We recommend the use of UFP finplugs. The most versatile and strongest finplugs, that are suitable for Futures and FCS systems. The only finplug on the market with recycled content. Learn more about how to set you Finboxes in right on our tutorial page:

Agave's ingenious fibre structure makes it much stronger than conventional foam, while still being extremely light. The stability is in the blank itself, the job is to make it water tolerant and resistant in the long term. The sealing step, in which the fibres of the blank get closed, is more important than the lamination itself. The Sealing makes the blank water-resistant and prevents it from becoming soaked. After you have successfully applied the sealing to the Agave board, you can laminate the surfboard as usual.

Regarding the durability of the surfboard, we recommend laminating it with bio-epoxy resin and a fibremat material of your choice. This construction makes the agave board extremely stable and resistant to dings, which is a significant advantage from a sustainability perspective: The high stability reduces the need for new production and therefore the consume of resources. It is also possible to laminate with polyester resin.

For laminating tips with the Agave, learn more on our tutorial page:

Our partners in Kenya “Growblanks” cut around 500 agave stems per day during the harvest season. The flower stems are sorted into different densities, standard, light and very light. Each plant grows with slightly different characteristics. Only the large mass makes it possible to sort them according to similar density characteristics and glue them together into blanks. Thanks to years of experience and harvesting, the farm is also able to replant the premium plants to ensure the best possible quality for the blanks.

It is necessary to make a filler coat with Eco Epoxy and Aerosil (silica) 50/50 by volume.

WHY?

The fiber structure of agave is full of air, similar to a long bundle of straws. This feature makes the Agave so light but also strong. It is also beneficial in case of dings, as water will run along the grain and not penetrate the core of the surfboard. Before lamination, it is important to close the fibers with a sealing step, similar to EPS foam.

Learn more about how to make a sealing on an agave Surfboard on our tutorial page.

The blanks do not have a stringer but a middle pole that shapers can use as a guide. Here you simply mark half of the middle stem and can be sure to have the center. Why the Agave blanks don't have a stringer is because they don't need it due to their fiber structure. You can imagine that the entire blank consists of many stringers. The only difference is that they are holistic, like a lot of straws close together. This makes them incredibly light, but also very stable.

Yes, agave is the natural material that is most similar to foam. You can CNC mill the agave, but you can also handshape it. Before lamination, the agave needs a sealing step, as with EPS foam. The following link brings you to our tutorial page, where you will be guided step by step through the working steps with the agave:

You can compare our very light blanks with the weight of a standard PU foam. Our standard is about 100-300g heavier than a standard PU foam if we dont hollow it out, otherwise it could be the same. It is important to note that there is more to the weight of a finished surfboard than just the core material.

We’ve got 14 different sizes and for every size, 4 different densities:

- Super Light 45-50 kg/m³

- Very light: 50-55 kg/m³

- Light: 55-60 kg/m³

- Standard: 60-65 kg/m³

The Agave has similar properties to foam in terms of flex and weight.

One difference is the pleasant rebound effect of the agave, which can also be found in skis or skateboards. This gives the flex life, as the board reacts much more intensively to the surfer's forces. It is important to mention, however, that this type of detail can only be felt by very experienced surfers

Our head office and largest blank warehouse is in Munich. To avoid long delivery distances and save you high delivery costs, we have Blank stocks in almost all surf hotspots in Europe. We are happy to have partners in Spain, Portugal, France and the UK who offer finest CNC preshapes for you in addition to local blank delivery.

We can confidently recommend the Agave for all shape types from longboards to performance shortboards. Agave is particularly suitable for boards that require high resistance, such as tow in boards, guns, foil boards and kiteboards.

The source of our agave blanks comes from a company based in Kenya called Grow Blanks. They are the first & only agave surfboard blank producing company in the world. Grow Blanks is based on one of the world’s largest agave sisal fibre producing farms with exclusive access to a vast amount of raw material. This allows Grow Blanks to produce blanks in quantities that can make a meaningful impact in the surf industry. Learn more about production, sustainability, the shaping process and the performance of agave here:

The agave plant is not a tree; it is actually a succulent. At the end of its lifespan, it grows a pole. Grow Blanks harvests these poles, dries them, and cuts them into pieces that form the blanks. The blanks are glued together at a ratio of 2:1 (water to wood glue). Grow Blanks delivers a unique quality of agave blanks worldwide. Each blank contains 18–25 stems. Grow Blanks sorts the material into four different density categories to provide consistent quality. This makes the shaping process easier and improves the performance of the boards.

Agave behaves like any other wood when exposed to water. As long as it can dry out well, there are no problems. Similar to certain types of foam, the structure of agave is absorbent. We therefore recommend that you use one of our primers before laminating or covering the board with other woods. If you do get a ding, we recommend either using our quick fix tape to continue surfing or allowing the board to dry out properly and to seal it again.

You can work the agave with the same tools as with conventional foam. We recommend working with the planer as much as possible, as this is originally made for wood and cuts the agave even better than you are used to with foam.

It is good to know that there are 10 to 30 different agave plants in a blank. Growblanks has the ability to offer 3 different densities because of their enormous ranch of plants on the farm which they sort into very light, light and standard poles. When sanding it is important to understand that there are multiple plants in your blank that may have naturally slightly different densities. This can be a little challenge when sanding the nose and tail. Sand with care, watch in between!

Learn more about each working step with the agave blank on our tutorial page

Any questions?

Josefstraße 23

Halle 50 a, 82178 Puchheim

Germany

info@ecosurfsupply.com

+49 (0) 1732054799